Centrifugal pump mechanical seal, also known as cross-section sealing, mainly by the dynamic ring, static ring, pressure components and sealing components and other components. The basic principle is that the moving ring presses the pressure of the liquid in the sealing cavity and the pressure of the pressing element so that the end face is adhered to the end face of the stationary ring, and an appropriate specific pressure is generated at the end faces of the two rings and a very thin layer is maintained. Liquid film to achieve the purpose of sealing.

During the operation of the pump, if the vibration of the shaft is directly transmitted to the sealing end surface without buffering, the sealing end surface cannot be closely fitted to increase the leakage, or the sealing surface wears seriously due to the excessive axial load. Fail to seal. In addition, the end face will inevitably wear due to friction, if there is no buffer compensation, it will inevitably cause the gap of the end face to become larger and larger and cannot be sealed.

There are many types of mechanical seals. Only balanced and unbalanced mechanical seals are described below.

Unbalanced type: The effective area B of the sealing medium acting on the moving ring (removing the area of ​​the part where the working pressure cancels out) is equal to or greater than the contact area A of the moving and stationary ring end surface. The pressure on the end surface at this time depends on the pressure of the sealing medium. The pressure of the medium increases, and the specific pressure on the end face increases in proportion. If the pressure on the end face is too large, it may result in serious seal leakage and shortened life. Therefore, unbalanced mechanical seals should not be used under high pressure.

Balance type: The effective area B of the sealing medium acting on the moving ring is less than the contact area A of the end surface. When the medium pressure increases, the pressure on the end surface increases slowly, that is, the pressure of the medium affects the specific pressure of the end surface less. Therefore, the balanced type can be used for mechanical seals under high pressure.

The mechanical seal device has a compact structure, small mechanical friction, and reliable sealing performance, but has a high manufacturing process requirement. In the muddy water, the dynamic and static laminating surfaces are easily worn to make the seal fail. Therefore, it is suitable for use in a clear water centrifugal pump.

During the operation of the pump, if the vibration of the shaft is directly transmitted to the sealing end surface without buffering, the sealing end surface cannot be closely fitted to increase the leakage, or the sealing surface wears seriously due to the excessive axial load. Fail to seal. In addition, the end face will inevitably wear due to friction, if there is no buffer compensation, it will inevitably cause the gap of the end face to become larger and larger and cannot be sealed.

There are many types of mechanical seals. Only balanced and unbalanced mechanical seals are described below.

Unbalanced type: The effective area B of the sealing medium acting on the moving ring (removing the area of ​​the part where the working pressure cancels out) is equal to or greater than the contact area A of the moving and stationary ring end surface. The pressure on the end surface at this time depends on the pressure of the sealing medium. The pressure of the medium increases, and the specific pressure on the end face increases in proportion. If the pressure on the end face is too large, it may result in serious seal leakage and shortened life. Therefore, unbalanced mechanical seals should not be used under high pressure.

Balance type: The effective area B of the sealing medium acting on the moving ring is less than the contact area A of the end surface. When the medium pressure increases, the pressure on the end surface increases slowly, that is, the pressure of the medium affects the specific pressure of the end surface less. Therefore, the balanced type can be used for mechanical seals under high pressure.

The mechanical seal device has a compact structure, small mechanical friction, and reliable sealing performance, but has a high manufacturing process requirement. In the muddy water, the dynamic and static laminating surfaces are easily worn to make the seal fail. Therefore, it is suitable for use in a clear water centrifugal pump.

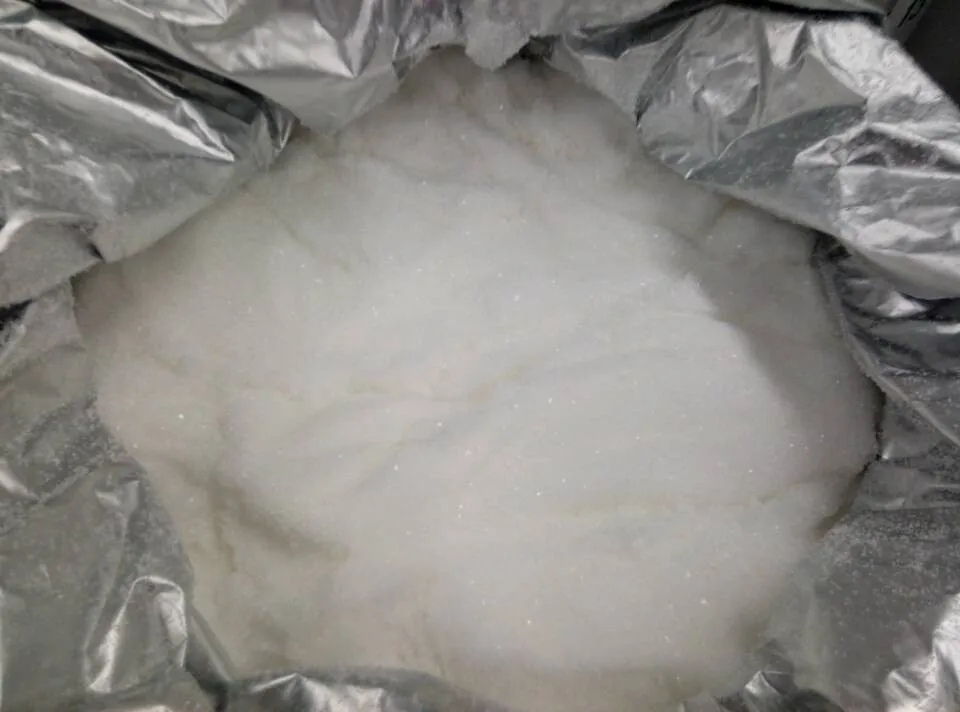

We provide kinds of solid monomer,like thymol,Natural borneol crystal,Menthol crystal,camphor,Synthetic Borneol,Cinnamic Acid,etc.

They can be widely used in chemical,flavor,medical,etc.

Standard cardboard drum is 25kgs in a drum

Small package 1kg,5kgs,10kgs in a drum

Please contact us for more details

Solid Monomer

Cinnamic Acid,Solid Monomer,Synthetic Borneol,Menthol Crystal

Jiangxi Global Natural Spice Co., Ltd. , https://www.chessentialoil.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)