Magnesium and magnesium alloys have the advantages of light weight, high specific strength, small elastic molds, good thermal conductivity, easy recovery, and low environmental pollution. They have important applications in the automotive, mechanical and electronic, aerospace, defense industry, transportation and other fields. value. Magnesium alloys are difficult to plastically form and are usually formed by extrusion methods with excellent deformation mechanical conditions. With the advancement of science and technology, the market demand for product quality has been continuously increasing, and the mold has played an important role in the magnesium alloy extrusion molding. The literature shows that there are few researches on the structure of magnesium alloy extrusion die at home and abroad, especially for the study of profile extrusion die. This experiment explored the effect of different mold structures on the extrusion process of magnesium alloy profiles.

1 mold structure characteristics and extrusion process

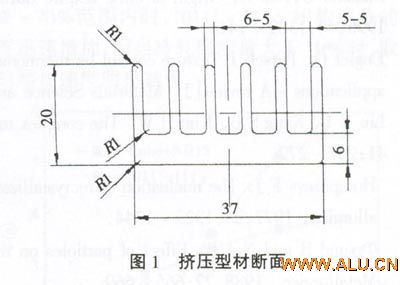

Because the deformation force required for extruding the magnesium alloy at high temperature is large, and the fin profile has higher teeth, the mold can easily break at the cantilever during the high temperature extrusion, and collapse or collapse. In this study, a computer heat sink profile (Figure 1) was used as the research object, and three typical molds were used to perform the magnesium alloy extrusion. Mold material selection 4Cr5MoSiV1

1.1 mold structure characteristics

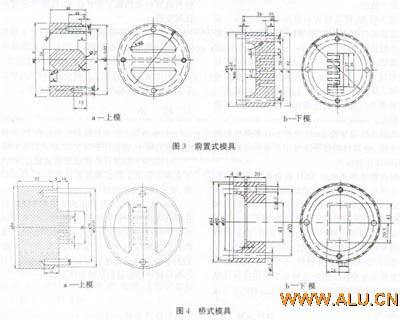

Flat die is a more common die for producing solid profiles. Its structure is simple and the extrusion force required for forming is large. Fig. 2 is an improved tapered die structure on the basis of a flat die. Compared to a flat die, the taper angle in the tapered die contributes to the flow of the metal when it is deformed, reducing the pressing force.

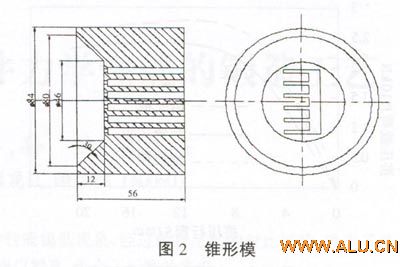

Figure 3 is a front mold. The feature is that the two split holes in the upper die are symmetrically distributed, and the welding chamber is in the lower die; at the same time, due to the shielding effect of the upper die's diversion bridge on the cantilever part of the lower die, the direct impact of the extrusion force on the lower die suspension part is reduced. , to protect the role of mold.

Figure 4 is a bridge die. The lower die is a simple rectangular hole, and there are several forming grooves on the upper die core for the superconducting flow and forming of the magnesium alloy. Compared with the front mold, there is no cantilever in the mold structure, and the core and the rectangular hole of the lower mold interact with each other, and the teeth on the heat sink are formed during extrusion. All the forces are transferred to the upper die and the core, thus ensuring the strength of the die.

1.1 Extrusion process

The extrusion equipment is a 3MN vertical hydraulic extruder. Magnesium alloy ingot size diameter 82mmX150mm, the heating temperature of the ingot according to the magnesium alloy phase diagram, plastic map and recrystallization diagram is set to 420 °C, the extrusion speed is controlled between 15mm/s~25mm/s, the extrusion cylinder and The preheating temperature of the mold is 350°C and 400°C, respectively.

2 test results and analysis

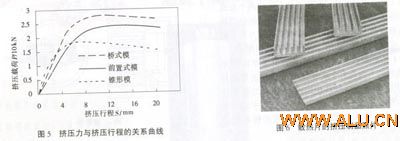

FIG. 5 and Table 1 are respectively the relationship between the extrusion force and the stroke in the extrusion test of the article shown in FIG. 1 and the relationship between the die structure and the larger extrusion force.

Figure 5 shows: the tapered die in the extrusion stroke of about 7mm, the extrusion force to a greater value of 1850kn, the front die and bridge die extrusion stroke of about 12mm, the extrusion force reached a large value of 2400kn And 2800kn. In the initial stage of extrusion, the extrusion force rises sharply with the increase of the stroke. When using the conical die, the stroke required for the extrusion force to reach the extreme value is longer, because the product is filled with a metal before extrusion. Due to the welding process of the mold welding chamber and the metal, the peak of the extrusion force appears later and larger. Three kinds of mold structure, its load and the shape of the stroke curve are basically the same.

As can be seen from FIG. 5 , the die structure has a greater influence on the extrusion, and the extrusion pressure required for the bridge die is larger, the front die is the next, and the extrusion that requires less extrusion is the taper die.

In the conical extrusion molding process, the conical cavity acts as a guide, and no welding is required during the metal forming process. The original required extrusion force is relatively small. Structurally speaking, since the split die has one more shunt and weld process than the taper die, the split die requires a greater pressing force than the flat die and the tapered die.

The bridge mold structure has a core, and there are a plurality of diversion grooves for the shaped product on the core. The force required for welding the metal material in the diversion groove is large, and the corresponding extrusion force is also large.

The products of AZ31 magnesium alloy heat sinks extruded using various molds are shown in FIG. 6 . Due to the adoption of the bridge die and the front die extrusion process through the flow separation and welding process, in order to determine the welding of the product, the scanning electron microscope was used to observe and analyze the microstructure of the metal in the die weld chamber and the profile weld zone. The results show that the product has no weld at the weld location, and the organization in the weld zone is dense, with no significant difference from the matrix, indicating that the weld is in good condition.

The front-mounted splitter did not show any collapse or other deformation after the test. Although the pressing force of the required root is large, the shield cantilever does not show any deformation due to the protection of the cantilever by the diverting bridge.

Bridge die forming is more difficult. During the extrusion process, the flow resistance of the metal at the diversion groove at the core of the die is relatively large, which makes it difficult for the metal to flow out of the die hole. At the same time, due to the large difference in the wall thickness of the different parts of the product, the metal flow is not uniform, resulting in the core head being damaged. Non-uniform force produces a large shear force and torque on the core, resulting in a large squeeze.

3 Conclusion

1 In the three die extrusion processes designed, the pressure required by the cone die is smaller, the pre-protective die is the next, and the bridge die is larger.

2 Cone mold and pre-protection mold have better forming quality. The bridge mold has large flow resistance at the small groove on the core of the metal, and the extrusion welding is difficult, resulting in a large extrusion force during molding.

3 From the perspective of extrusion molding of the composite mold structure, AZ31 magnesium alloy can be completely welded in the welding chamber. The scanning electron microscope observation of the welding room and the product welding joint found that the microstructure is dense and has no significant difference with the matrix. The welding quality is better, which means that it is feasible to squeeze the AZ31 magnesium alloy radiator with a combination die, which can be applied to the extrusion of other solid profiles or hollow profile products.

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)